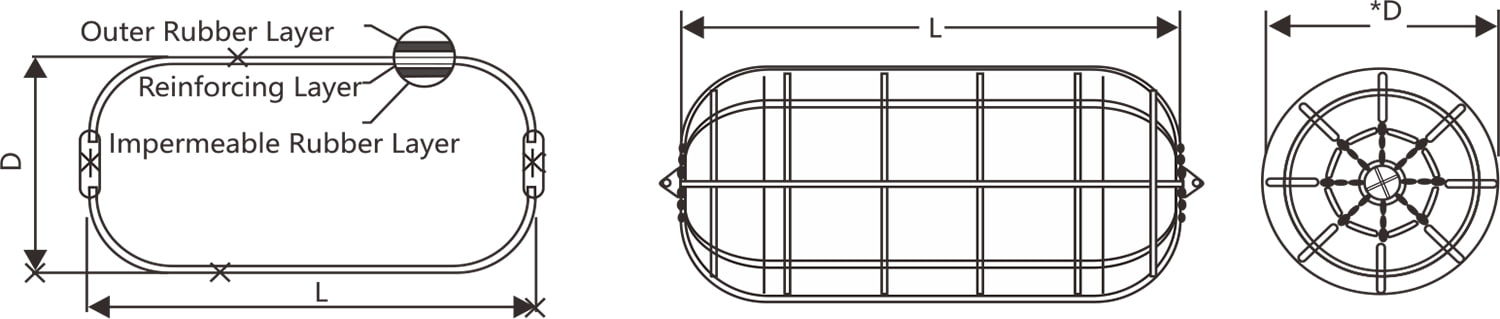

The Solid Floating Fender is engineered to provide low reaction force while absorbing significant amounts of energy during vessel impacts. Reaction force is the force exerted back onto the vessel when the fender is compressed upon impact. Traditional fender systems can often transmit considerable forces back to the ship, which can cause damage to the vessel's hull and affect its operational integrity. The Solid Floating Fender, however, is designed to minimize this reaction force, thereby reducing the risk of structural damage to the ship.

Additionally, the fender’s design allows it to absorb and dissipate impact energy effectively. This capability ensures that the energy from collisions is managed efficiently, protecting both the vessel and the fender system itself. The result is a reduced likelihood of damage and maintenance issues, contributing to a safer and more cost-effective maritime operation.

One of the key advantages of the Solid Floating Fender is its ability to exert minimal surface pressure on the side of the ship. The product is designed to handle surface pressures of up to approximately 14 tons per square meter. This low surface pressure is crucial for protecting the ship’s hull from damage during docking. By spreading the impact force over a larger area, the fender helps prevent localized pressure points that could cause hull deformation or coating damage.

This feature is particularly important for large ships, where maintaining the integrity of the hull is essential for both safety and operational efficiency. The ability to manage surface pressure effectively ensures that the ship's structure remains intact, even under heavy impact conditions.

The fender’s design also includes outstanding oblique compression performance. This means that the fender can effectively absorb and manage impacts that occur at an angle, rather than just direct, head-on collisions. This is particularly important in maritime environments where vessels may approach or dock at various angles due to wind, current, or navigational constraints.

The oblique compression capability allows the fender to adapt to different impact scenarios, providing reliable protection regardless of the angle of contact. This flexibility enhances the overall effectiveness of the fender system, ensuring that it performs well under a variety of operational conditions.

Another significant feature of the Solid Floating Fender is its outstanding floating performance and adaptability to changing water levels. The fender is designed to remain effective regardless of fluctuations in tide levels. This is achieved through its buoyant construction, which allows it to float and adjust to different water levels, maintaining consistent protection for the vessel.

The ability to adapt to tide level changes is particularly important in regions with significant tidal variations. By accommodating these changes, the fender ensures that vessels receive uninterrupted protection throughout their berthing or transfer operations, regardless of the environmental conditions.

The use of compressed air as a buffer medium in the Solid Floating Fender provides outstanding cold resistance. This feature ensures that the fender maintains its performance and flexibility even in low-temperature environments. Cold resistance is crucial for operations in colder climates or during winter months, where temperature fluctuations can impact the performance of conventional fender systems.

By maintaining its structural integrity and functionality in cold conditions, the Solid Floating Fender ensures reliable protection throughout the year, regardless of seasonal temperature variations.

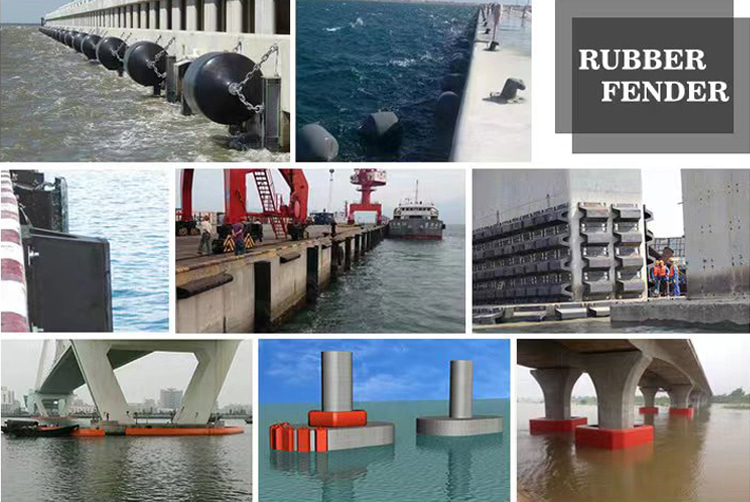

The Solid Floating Fender is particularly well-suited for large ships and sea lighters, as well as for offshore transfer operations. Its robust construction, high energy absorption capacity, and adaptability to various environmental conditions make it an ideal choice for protecting large vessels during docking and transfer operations.

English

English 中文简体

中文简体